Achieving energy and cost saving with a relatively little water

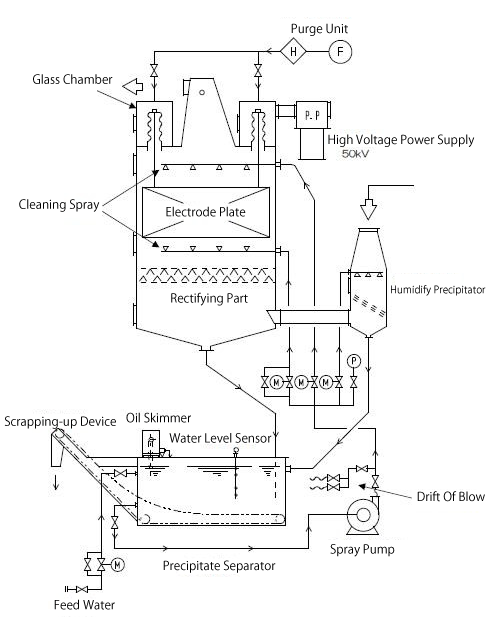

It is different from a conventional Wet Electrostatic Precipitator that water of our “Wet ST-Model” for cleaning dusts is mist. Thus, it can save total amount of water more than conventional ones flushing at all the times (eg. approx. 4000ℓ per hour → approx.100ℓ per hour). That contributes to save energy due to less water to use and also reduce the cost.

–

both of horizontal & vertical type are available

“Wet ST-Model” has both of horizontal and vertical type so that companies can choose them based on their needs and conditions such as the application, location to be installed etc.

–

–

–

Easy maintenance because of automated cleaning system.

Dust collected to a dust collection electrode by an electrostatic precipitator part flows down naturally with mist sprayed. However, some of the dust sometimes remains. Thus, it keeps clean by cleaning the dust collection electrodes automatically after stopping the operation. No extra labor cost and work such as cleaning/changing the filter like Bug Filter Dust Collector.

–

Long-lasting

It is long-lasting because the machine needs much less consumer goods than conventional ones. Thus, users can use them without changing many parts for a long time.

–

–

–

–

–

companies / factories planning to collect small dust properly

“Wet ST-Model” is able to collect both solid dust and liquid dust, especially in factories exhausting small dust such as iron particles and oil fumes. On the other hand, we recommend Hybrid Wet Electrostatic Precipitator for factories exhausting larger dust such as rubbers, resin, films and tapes.

–

–

–

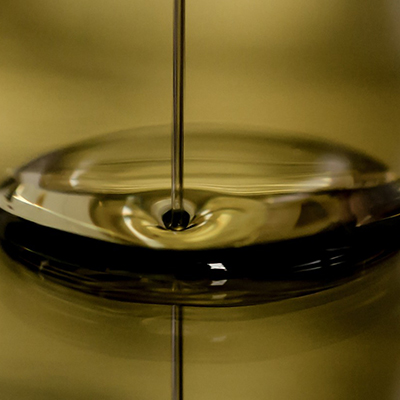

companies / factories planning to collect flammable oil mist

“Wet ST-Model” has contributed toward the reduction of fire risks, because it collects flammable dust like oil mist with water. If a fire were to occur, Hybrid Wet Electrostatic Precipitator stops its operation and extinguishes a fire by water spray automatically by its internal temperature inspector installed in it, so that it is safe.

companies / factories planning to collect adhesive dusts such as welding fumes

Adhesive dusts occur in factories welding steel pipes. Bag Filter Type Precipitators are clogged without frequent cleaning and checking, so it has a deteriorating effect on collecting dusts and also affects the production line. However, “Wet ST-Model”It has no bag filters so that no worry about clogging.

–

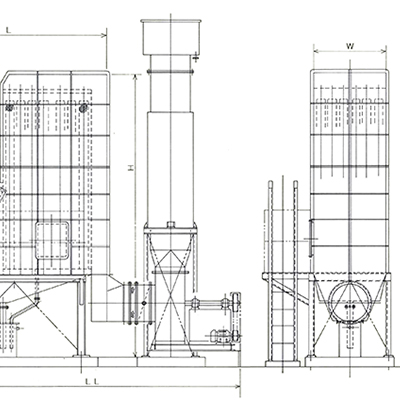

Product blueprint

- “Hybrid Wet Electrostatic Precipitator” cleans the gases containing dust via two parts of disposal process, one is water saved type scrubber part (processing the dust by vigorously contacting with pooled water) and the other one is electrostatic precipitator part.

- Dirty gases flowing into the machine from suction get vigorously contacted with stirred water in the scrubber part. In the process, larger dust are removed from the gases. After that, the gases and mist occurred in the scrubber part get charged by Corona Discharge through the electrostatic precipitator part. In the process, smaller dust is separated and collected. In the end, clean air comes out from the exhaust port.