Water for dust collecting is reused in full circulation without the occurrence of a secondary pollution by discharging the water.

Water consumption is much less because of no need to discharge water.

collecting most of dust more than 0.5μm.

space-saving due to its compact size. Easy to maintenance due to its simple structure.

- “RSE Scrubber” is a high performance wet type precipitator that dust collecting water is reused in full circulation.Gas rates standardize up to 50~1,000m3/min for 15models. Meeting up to 1,0000m3/min, depending on combinations.

- It is effective to collect most of dust more than 0.5μm. Furthermore it can keep down the exhaust gas concentration less than 0.1g/m3 for 10g/m3 in dust concentration.

- Water is supplied automatically by ball tap valve so that all you need to do is just to re-supply water for the amount of water adhering evaporated moisture and dust. Therefore, water consumption for dust collecting is much less than conventional equipment.

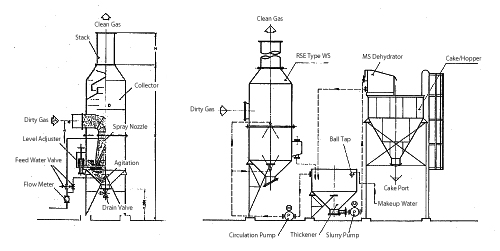

Product Blueprint

This machine is designed by a motto, “Simple is Best”. It is constituted with RSE scrubber (Caging, Inner cylinder, Baffle, Mist separator and Level adjuster), compact type thicker, MS dehydrator, Cake hopper and Slurry pump, so that you can install the machines at any place due to its compact sizes.

3 key factors for Structure

- “RSE Scrubber” belongs to a water saved type wet type precipitator (Water Type Scrubber) so that it is easy to treat wastewater and also energy saving for pumping power.

- It is not spray type, so there is no trouble caused by nozzle clogging of a spray.

- It efficiently separates and collects dust in the gas of inner cylinder by having an inertial impingement and an interruption with a drop of water and contacting with a liquid film.

- It is easy to adjust surface of water for dust collecting so that so you can customize loss of pressure and collecting efficiency based as you like.

- A MS dehydrator dehydrates and translates with providing positive and negative pressure by diaphragm to undersurface of a slope screen by running slurry on the slope screen.

- More compact size is possible unless you need a cake hopper.

Standard size chart

| Type | Gas Rate m3/min. |

Outer Diameter D (mm) |

H (mm) |

h (mm) |

Ød (mm) |

X (mm) |

|---|---|---|---|---|---|---|

| RSE-700 | 50 | 700 | 3,830 | 2,335 | 235 | 1,000 |

| RSE-750 | 60 | 750 | 3,975 | 2,440 | 265 | 1,000 |

| RSE-850 | 75 | 850 | 4,165 | 2,575 | 300 | 1,000 |

| RSE-950 | 95 | 950 | 4,355 | 2,710 | 335 | 1,000 |

| RSE-1050 | 115 | 1,050 | 4,605 | 2,900 | 375 | 1,500 |

| RSE-1200 | 155 | 1,200 | 4,920 | 3,125 | 425 | 1,500 |

| RSE-1300 | 185 | 1,300 | 5,180 | 3,325 | 475 | 1,500 |

| RSE-1500 | 235 | 1,500 | 5,550 | 3,580 | 530 | 1,500 |

| RSE-1700 | 300 | 1,700 | 5,930 | 3,850 | 600 | 2,000 |

| RSE-1900 | 375 | 1,900 | 6,310 | 4,120 | 670 | 2,000 |

| RSE-2150 | 490 | 2,150 | 6,755 | 4,425 | 750 | 2,000 |

| RSE-2350 | 595 | 2,350 | 7,185 | 4,725 | 850 | 2,000 |

| RSE-2-1900 | 750 | 1,700×3,400 | 6,575 | 4,265 | 950 | 2,000 |

| RSE-2-2000 | 850 | 1,800×3,600 | 6,840 | 4,425 | 1,000 | 2,000 |

| RSE-2-2150 | 1,000 | 1,900×3,900 | 7,100 | 4,585 | 1,050 | 2,000 |

space chart

| Type | Installation Area A×Bm |

Thickener CapacityD (m3) |

Hopper Capacity (m3) |

Installation Area (m) |

Power Requirement (kW) |

|---|---|---|---|---|---|

| RSE-700 | 1.7×1.0 | 4.0 | – | 3.0×3.0 | 7 |

| RSE-750 | 1.8×1.1 | 4.0 | – | 3.0×3.0 | 7 |

| RSE-850 | 1.9×1.2 | 4.0 | – | 3.0×4.0 | 7 |

| RSE-950 | 2.0×1.3 | 4.0 | – | 3.0×4.5 | 7 |

| RSE-1050 | 2.0×1.4 | 4.0 | – | 3.0×4.5 | 7 |

| RSE-1200 | 2.2×1.5 | 4.0 | – | 3.0×4.5 | 7 |

| RSE-1300 | 2.3×1.6 | 4.0 | 9.6 | 3.0×5.0 | 9 |

| RSE-1500 | 2.5×1.8 | 4.0 | 9.6 | 3.0×5.0 | 9 |

| RSE-1700 | 2.8×2.0 | 4.0 | 9.6 | 3.0×7.5 | 9 |

| RSE-1900 | 3.0×2.2 | 4.0 | 9.6 | 3.0×7.5 | 9 |

| RSE-2150 | 3.3×2.5 | 8.5 | 9.6 | 3.5×8.5 | 10 |

| RSE-2350 | 3.5×2.7 | 8.5 | 9.6 | 3.5×8.5 | 10 |

| RSE-2-1900 | 2.9×4.4 | 15.0 | 9.6 | 5.0×9.0 | 10 |

| RSE-2-2000 | 3.0×4.6 | 15.0 | 9.6 | 5.0×9.0 | 10 |

| RSE-2-2150 | 3.1×4.9 | 25.0 | 9.6 | 5.0×9.0 | 10 |